GembusHub overview

The main features of GembusHub

- Control and monitor up to 400 Gemstarts

- Scan 400 Gemstarts in under 500ms

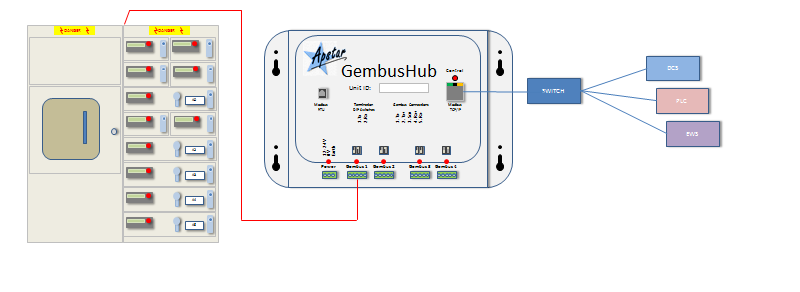

- RS485 ports x 4 for direct connection to Gemstart

- Up to 16 controlling devices can connect as Modbus TCP/IP Clients

- All of the Gembus ports (1-4) can be configured to allow serial access to PLC/DCS devices.

- Uses the native Gemstart protocol: Gembus

- Link speeds up to 115200 (the Gemstarts may not be able to match the higher speeds)

- Configuration data for all 400 Gemstarts retained through a power down

- Full support for Group Data, Configuration Data, Broadcast commands, Group Control

- Compatible with Gemstart 1 to Gemstart 5

When upgrading an old system the GembusHub can use the existing serial link wiring. Simply transfer the wires to the GembusHub. Alernativley it can be used on a new system and new cabling provided. It is very easy to connect:

Termination resistors are provided, and are easily accessed on the front of the unit.

The primary control access point is the ethernet port on the front of the unit. Normally a single device would connect but up to 16 devices can act as Modbust TCP/IP clients. These devices can then monitor Gemstart status and issue contol commands. Any device that supports Modbus TCP/IP can be used.

As an alternative any of the four Gembus ports can be reconfigured as Control access ports. So if you have a serial interface that can act as a Modbus RTU master then this can be used to monitor and control the attached Gemstarts. Please note: these are four wire only.

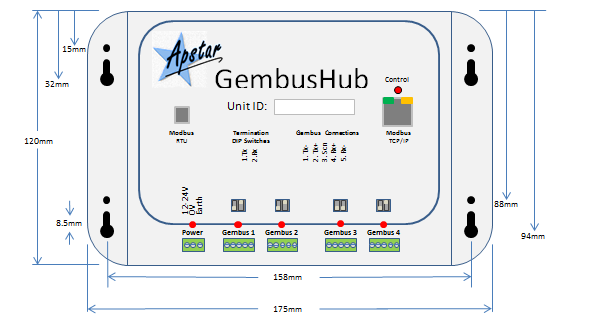

The unit is packaged as a small DIN rail mountable unit:

Alternativley the GembusHub can be attached directly to the panel back plate.

The GembusHub requires some configuration to allow the correct extraction of data for clients to read. Configuration of the GembusHub can be done in two different ways:

- Use the GembusHub Configuration Utility, GembusHubView.

- Use program code in an attached client

The GembusHub configuration program is a simple Microsoft Windows utility that allows the various settings of the GembusHub to be viewed and modified.

The same parameters required for configuration are avialble to Modbus clients. So for example an attached PLC can write values in to the Modbus locations that are used for the parameter storage. This would usually be when a system is powered up, or if a change is made.

Connect to us using:

Contact us for more information Tel +44 1782 834177

www.apstar.co.uk